About Hydrothermal treatment

Hydrothermal treatment is a processing method in which water at high temperature and high pressure is used to process organic substance for effective utilization.

Although the area of hydrothermal treatment is wide, it is used mostly in a relatively fuel efficient area.

Working conditions of equipment that normally used are ~240℃, ~3MPa.

【About water】

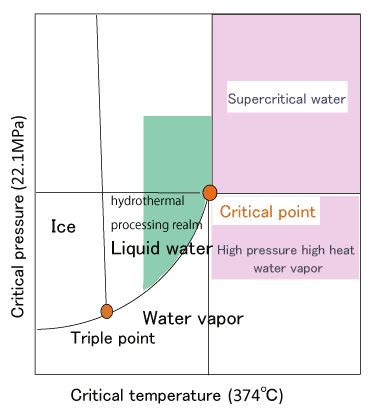

When pressure and temperature are applied to water in a closed container, the density of liquid and gas equalizes at a pressure of 22.1 MPa and a temperature of 374°C. (Cannot be distinguished)

This point is called “critical point”.

The state above the critical point is called supercritical.

The state below the critical point has the features of

・With great decomposition ability

・High compatibility with organic substance

With these kind of features it can decompose and dissolve organic substances.

The method of processing organic substances using water in this special state is called hydrothermal treatment.

Features of water at 200℃

■Low dielectric constant

While normal water`s dielectric constant is about 78, the high temperature high pressure water`s dielectric constant is about 30.

For this reason, with properties similar to alcohol, it is possible to dissolve oil.

■Large ionic product

The high temperature high pressure water has a very large ionic product. So it has great decomposition ability.

■Decompose organic substance into small molecules

In addition to the two features above, the water molecules under high temperature and pressure are in violent motion,

which can break the bonds of organic substances and lower their molecular weight.

To process bird`s hard feathers into liquid

To sterilize and liquidize the dead (died of sickness) pig (60kg) at the same time.

Liquefaction technology can be used as a raw material for liquid fertilizer, feed and methane fermentation.

It can be processed into powder form by treating with paper that absorbs moisture and woodchips.

Powdering technology can be used as a raw material for compost and as a powdered fuel.

Features of hydrothermal treatment

| Completely sealed process | Low energy loss and economical. There is no odor noise during processing. |

|---|---|

| High security | Pressure vessels comply with legal standards to ensure durability and safety. |

| Hydrothermal processing | Since there is no combustion, there will be no NOX, SOX, dioxin, or PM generated. |

| Short processing time | It takes 1.5 to 2.0 hours from input to processing to discharge. (Varies depending on the application) |

| High level of automation | After inputting raw material, you just have to press the button. After the processing is completed, a melody will ring out to inform you it has finished. |

| Economic | By using boiler, it can efficiently generate steam (more than 90%). Running cost is low. |

The fuel cost of high-performance hydrothermal processing equipment (subcritical equipment) is not high.

We manufacture from 2l (testing machines) to 15 m3 (large size) according to customers' need.

200ℓ(2MPa 210℃)

15000ℓ(15㎥ 2MPa 210℃)

Contact us

Please feel free to contact us at the following number.