Development of next-generation RPF (Refuse Paper & Plastic Fuel)

We aim to solve environmental problems by converting waste plastics and biomass waste into high-quality fuels from raw materials

- Theme:Realization of CO2 emission control and simultaneous solution of environmental problems caused by waste plastics

- Duration:2019~

- Name of Institute:Tohoku Electric Power Engineering & Construction Co., Inc., DA INVENT Co., Ltd.

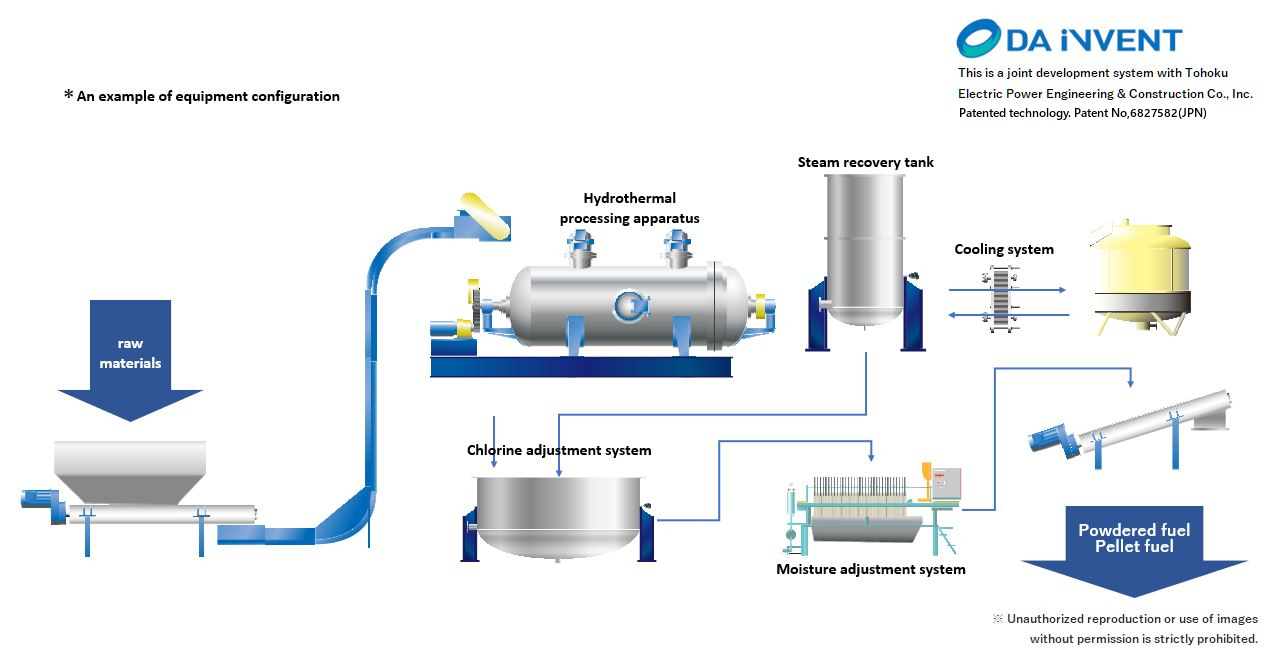

Next-generation RPF system

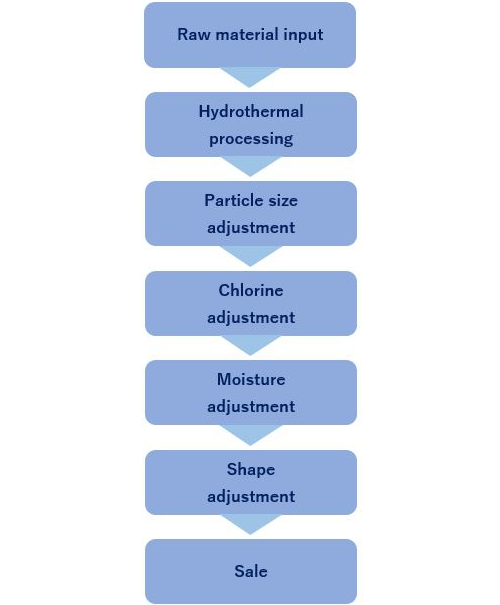

Flow chart

Product features

| Chlorine concentration |

0.1wt% or less |

|---|---|

| Shape | It can be processed into fuel shape which is suitable for boiler. |

| Calorific value |

The calorific value can be easily adjusted according to the boiler specifications. |

| Calorific value |

Due to high volatile content and low ash content, it is good in combustion quality and generates less combustion ash. |

| Self-heating | 0-3°C/5 days (53°C/3 days for coal). |

| Grindability | Hardgrove Grindability Index is about 150 and the load on the grinding equipment is low. |

| Hazardous trace substances |

Hazardous trace substances such as dioxin and heavy metals are contained and eluted below the standard value. |

| Economy | The unit price per calorific value is lower than that of coal or biomass fuel. |

| Environmentally friendly |

In the case of a product with a plastic ratio of 40 wt%, the amount of CO2 generated is about two fifths of that of coal, which can contribute to global warming countermeasures. |

This development was aimed at the following goals of the SDGs.

As an alternative fuel for coal and existing biomass, we aim to spread its use not only in Japan but also around the world.

・Promotion of waste recycling.

・Effective usage of unused energy.

・Expanded range of usage.

The waste that had been incinerated up to now is converted to high-quality fuel for use in high-efficiency boilers.

Used as a means to achieve the Energy Conservation Act at coal-fired power plants.

Contact us

Please feel free to contact us at the following number.